Extruded Heat Sink For Large Industrial Use

- Product Details

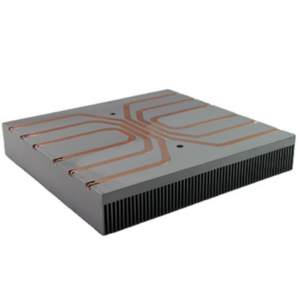

The heat sink is a device used to dissipate heat for components that are easy to heat. It is made of aluminum/copper materials with high thermal conductivity to make radiators of different shapes such as plate, sheet, and multiple pieces.| Extruded heat sink for large industrial use

The heat dissipation efficiency of the heat sink not only depends on the characteristics of the high thermal conductivity of the heat sink material, but also the heat capacity of the heat dissipation medium of the heat sink and the effective heat dissipation area of the heat sink. The radiator materials are mostly made of copper and aluminum. Copper has good thermal conductivity, is more expensive, difficult to process, too heavy, has a small heat capacity, and is easy to oxidize. Aluminum is lighter and has worse thermal conductivity than copper. Generally speaking, for heat sinks made of the same material and technology, the thicker the heat sink material and the larger the surface area, the better the heat dissipation effect.

Our heat sink mainly includes: aluminum extrusion + CNC machining large heat sink, FSW large heat sink, riveted heat sink, insert heat sink, heat pipe heat dissipation system, shovel heat sink, forged heat sink, application It is used to solve the heat dissipation solution of industrial automation, power & transmission, medical equipment, new energy transportation, instrument and testing equipment and other industries.

Extruded heat sinks are generally high-power heat dissipation components and heat dissipation systems. Based on the existing mature aluminum extrusion heat sink technology, our company can provide reliable natural convection environmental solutions. The aluminum extrusion molding is realized through the mold, and the complex heat dissipation gear structure can be realized. These complex heat-dissipating gears increase the heat-dissipating surface area and reduce the cost and time of aluminum block processing.

Advantages of extruded heat sink:

(1) It is more efficient than stamping and forming heat sink;

(2) More cost-saving than mechanical processing;

(3) There are a variety of standard shapes and sizes to choose from;

(4) Easy customization is lighter than copper, with obvious advantages;

(5) The MAX CLIP fastener system does not need to install hardware and tools.