What is Water Cooling Plate

Water cooling plates, also known as liquid cold plates or water blocks, are innovative heat dissipation solutions designed to effectively manage the thermal challenges faced by high-performance applications. These plates utilize liquid cooling technology to remove heat from critical areas in various systems, ensuring optimal performance and reliability. In this article, we will explore the features, benefits, and applications of water cooling plates, highlighting their crucial role in thermal management.

Features and Design:

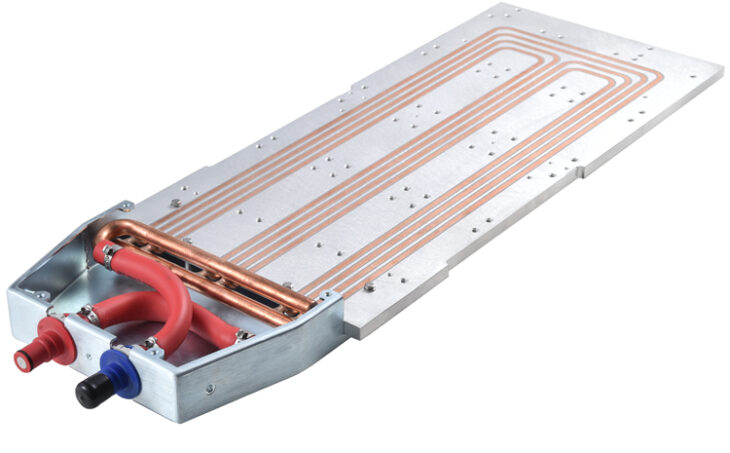

Water cooling plates are meticulously engineered to provide exceptional thermal performance and mechanical integrity. They are available in various configurations and designs to meet specific application requirements. Some notable features include

Channels and Turbulators: Water cooling plates offer flexibility in channel design, allowing for efficient heat transfer and fluid flow. Turbulators further enhance heat dissipation by promoting turbulence and increasing the contact area between the coolant and the plate surface.

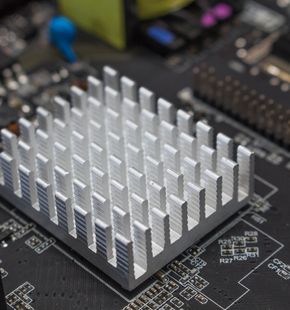

Construction Materials: These plates are typically constructed using high-quality materials such as copper, stainless steel, or aluminum. The choice of material depends on factors such as thermal conductivity, corrosion resistance, and cost-effectiveness.

Customization Options: Manufacturers offer customization services, allowing customers to design and optimize water cooling plates according to their specific needs. This ensures a perfect fit for the application and maximizes thermal efficiency.

The sealing techniques for water cooling plates generally include the following:

Protected Gas Tunnel Furnace Liquid Cooling Plates, Vacuum Brazing Liquid Cooling Plates, Embedded Pipeline Liquid Cooling Plates, O-Ring Sealed Liquid Cooling Plates, Friction Stir Welding Liquid Cooling Plates, Deep Hole Machining Liquid Cooling Plates, Microchannel Liquid Cooling Plates

Benefits and Advantages:

Water cooling plates offer several benefits compared to traditional air-cooling methods. Here are some notable advantages:

Enhanced Cooling Efficiency: Liquid cooling provides superior heat dissipation capabilities compared to air cooling. Water has a higher heat capacity and thermal conductivity, allowing it to absorb and transfer heat more effectively. This results in lower operating temperatures and improved overall system performance.

Compact and Lightweight Design: Water cooling plates are designed to be compact and lightweight, making them suitable for applications where space is limited. Their efficient heat transfer properties enable the design of smaller and more compact systems without compromising performance.

Low Noise Operation: Water cooling plates operate silently since they do not rely on fans or blowers for heat dissipation. This makes them ideal for noise-sensitive environments, such as audio recording studios or residential settings.

Customizability: Manufacturers offer a range of customization options, allowing customers to tailor water cooling plates to their specific requirements. This includes optimizing channel design, dimensions, and material selection, resulting in an optimized cooling solution

Large commercial LED displays are gradually becoming popular in industries such as exhibitions, sports events, and media. Water cooling technology, as a heat dissipation technique, provides better display performance and reliability for these large LED displays.

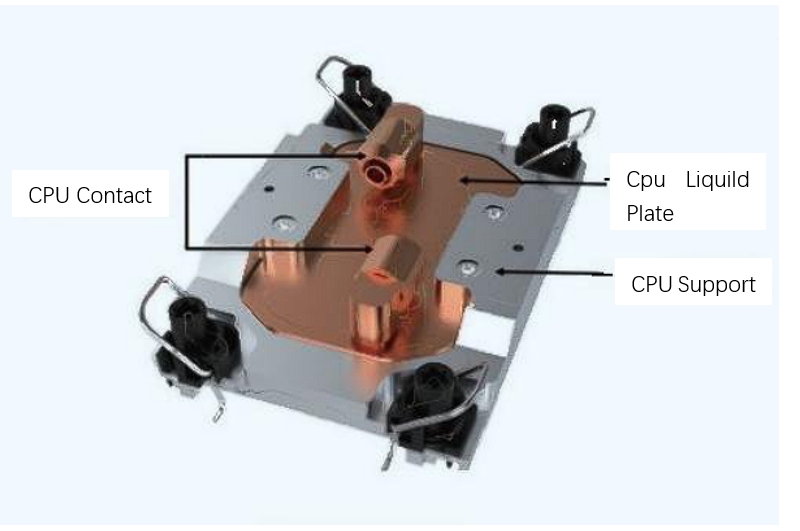

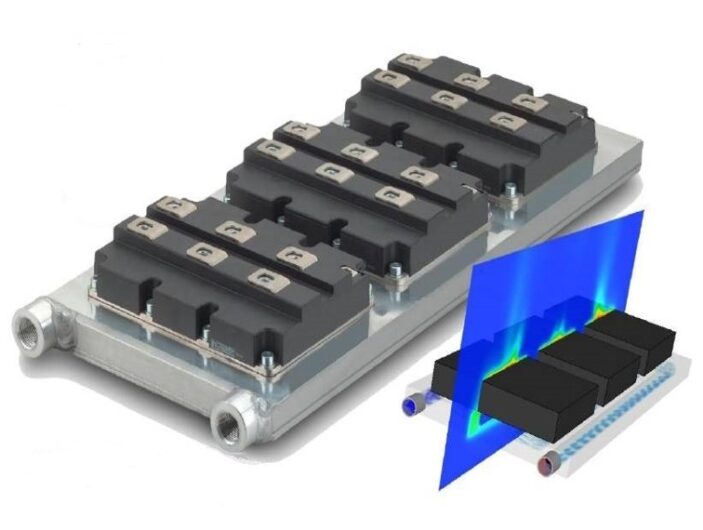

Electronics Cooling: They are widely used in electronic devices, such as power electronics, laser diodes, high-performance CPUs, GPUs, and FPGA-based systems. Water cooling plates effectively manage the heat generated by these components, ensuring their reliable operation

Water cooling plates are widely used in the field of communication, including heat dissipation for fiber optic communication devices, communication base stations, data centers, radio equipment, and power systems. Their efficient heat dissipation performance and thermal management capabilities make them an ideal choice for communication equipment.

Industrial Applications: Water cooling plates are utilized in industrial equipment, such as power supplies, welding machines, and high-power laser systems, where efficient heat dissipation is essential for reliable operation.

Medical and Scientific Instruments: Water cooling plates are employed in medical imaging equipment, analytical instruments, and laboratory devices to maintain stable operating temperatures and safeguard sensitive components.

Automotive and Aerospace: These plates play a crucial role in cooling electric vehicle power electronics, battery management systems, and aerospace avionics to ensure optimal performance and longevity

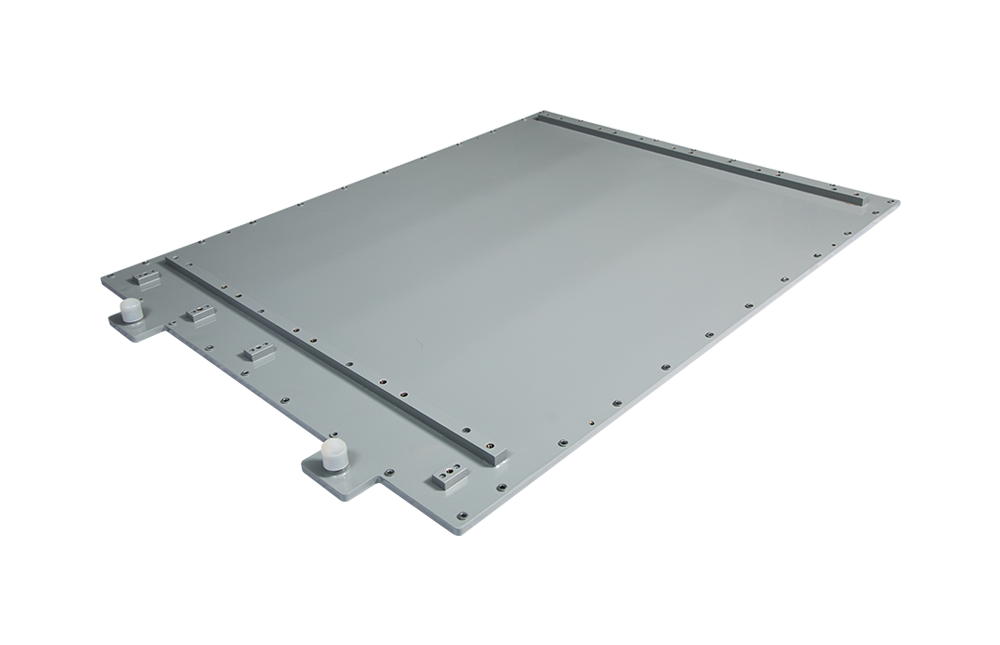

Custom Design Cold Plate For Your Busines

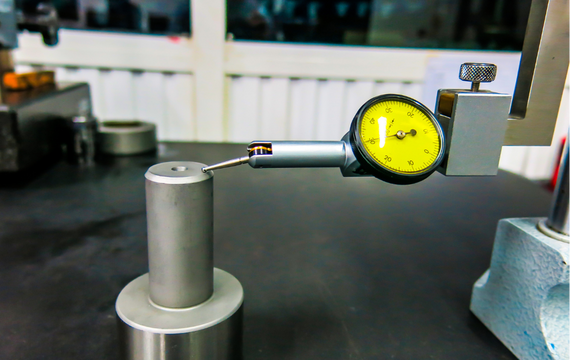

You can choose to customize your cold plate , which includes the size of the cold plate, material, etc., and Regis can help you to achieve it. And Regis will do reliability testing for each of your cold plates to ensure that the product is ready for use.

Optimized thermal design

If the thermal solution proposed by the customer does not meet the customer’s needs, Regis will optimize the thermal design on the basis of the customer’s solution. And Regis ensure that the optimized thermal solution will meet the customer’s needs.

The advantages of Regis

We have a wealth of experience in designing and processing cold plates. We are committed to producing a wide variety of cold plates to meet the needs of our customers. Our internal control of product quality is very strict to ensure that our products meet our customers’ needs.